A Floor Covering which is made completely by human hands by Handknotting, Handtufting or Handweaving, in which handspun Yarn of natural fibers (most commonly wool or silk) is used, with individual character and design. Hand-made carpets are traditionally more expensive than those made by machines. Though there are several carpet-making methods, including braiding, hand tying (or hand knotting), hooking, shearing and tufting, the most common of these are braiding and hand knotting.

Derived By : Carpet Export Promotion Council (CEPC) India

Derived By : Carpet Export Promotion Council (CEPC) India

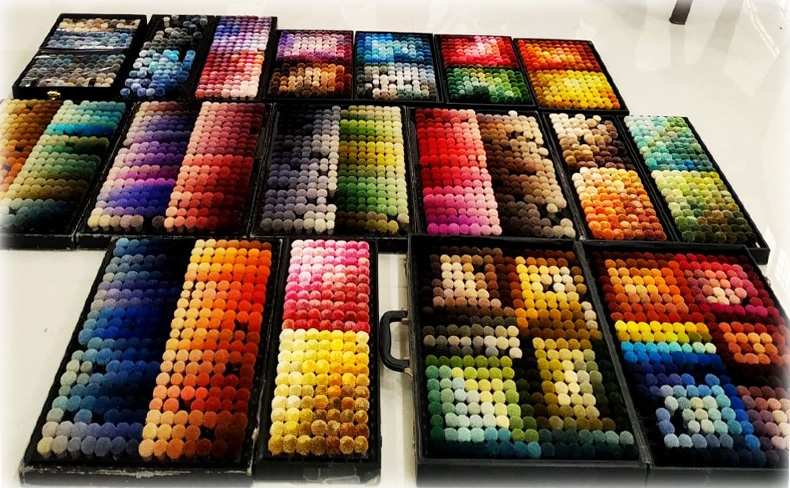

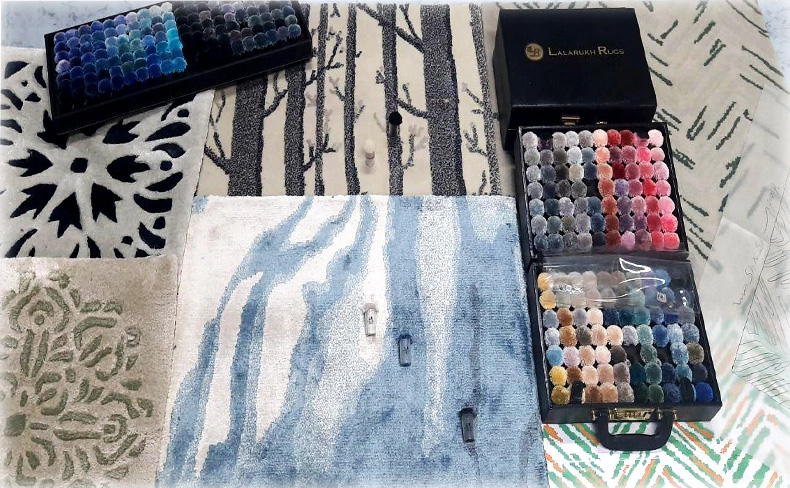

We use Color Tufts & Benjamin Moore to match the color perfectly, We also manufacture our own Color tufts box and send it to our clients for our convenince. We have different sections as per the type of yarn, and varieties, these are wool and viscose yarns. We also use ARS color tuft as it is used globally.

The most important person in the dyeing process is the Dye Master. He is responsible for matching the colors and preparing the dyes. Each dye takes about a day to create. The yarns are dyed and then left to dry naturally in the sun on the rooftops.

We keep all the modern dyeing equipment for the dyeing of different types of yarns such as silk, Viscose, Tencel, Cotton, Jute, woolen, polyester, art silk, etc.

After yarns are dried up, they are fitted into wooden/metal rotating frames, where the workers warp the yarn into balls. The balls are separated by the color and thickness of the yarn. Later, balled yarns are given to weavers on the loom to weave the rug.

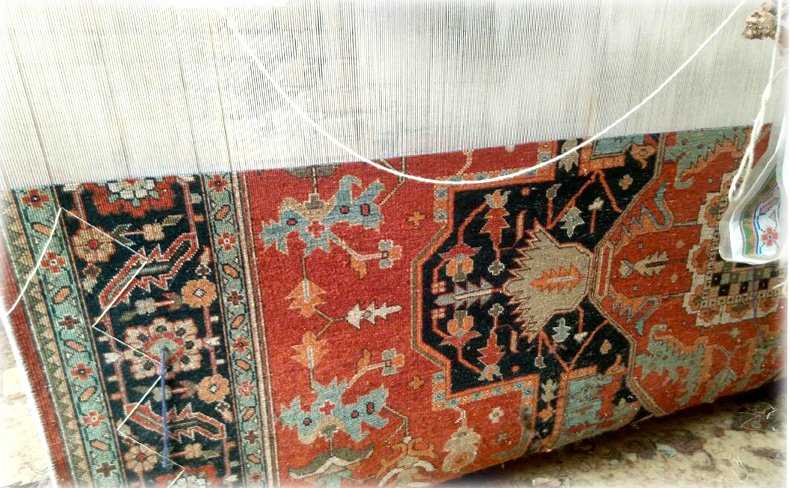

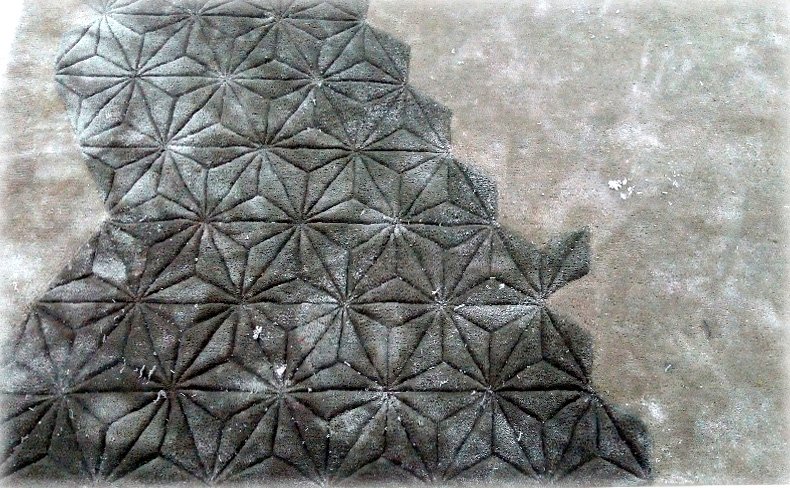

Our Tibetan & Persian rugs are Ancient techniques and passed down through many generations and the finest natural materials. The rug is composed of many thousands of individual knots, each one created by hand as the yarn is tightly knotted around the warp and weft of the rug and around a metal rod. The size of the knot determines the quality of the rug, with the smallest knots allowing the finest detail of the pattern. The result is a rug of extraordinary quality and durability.

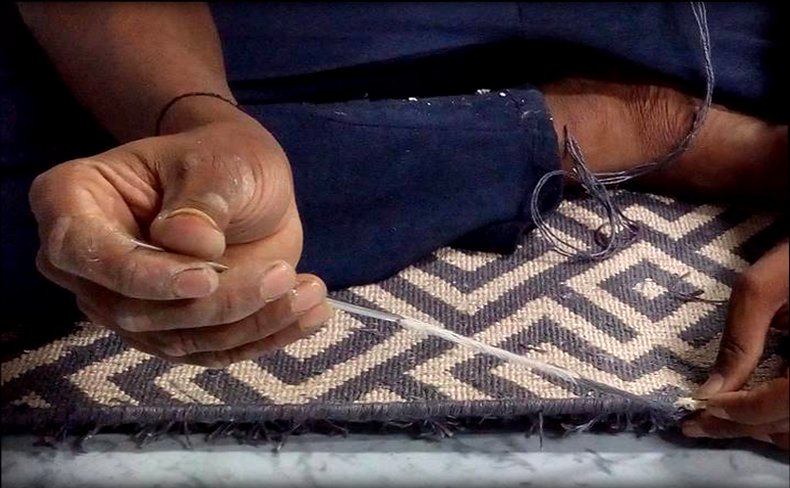

Threads are woven on a loom into colorful patterns, without the pile, flatweaves rugs are lighter, flexible, and reversible and the pattern is the same on both sides of the rug. Flatweave rugs are great examples of fine craftsmanship, they’re easier to make and typically cost less. Kilims & Dhurries display the same general weaving skill,

Our flatweave rugs are particularly durable, hold up well in high traffic areas and we offer a very competitive price for flatweave rugs.

These are done on a loom and the process takes 1-4 people depending on the size of the rug. On the loom, the yarn or weft is thrown through the middle of the bottom and top warp. Handwoven rugs have a beautiful loop pile, cut pile, or a mix of both in them. if you are eager to invest in a rug that is durable and able to withstand everyday use, it is likely that hand-woven rugs are for you. Our Handwoven carpets and rugs are made in our factory at Bhadohi by experienced Artisans.

A pattern is drawn on a primary backing material using the stencil. The backing material, usually made of cotton, is attached to a frame.

The weaver inserts tufts of wool into the backing material using a tufting tool. The primary backing material is then covered with a latex material and a secondary backing material is attached. Then the surface loop pile is sheared to create a flat surface with a dense pile.

Each & every rug are made in our factory at Bhadohi by experienced Artisans.

Very few types of decor have the prestige of Persian rugs. These handmade works of art have long been prized for their beautiful patterns, incredible craftsmanship, and outstanding durability. Persian rugs add timeless class to any room they are on. Techniques are carefully passed down from generation to generation.

A latex coating is applied to the back of the rugs It is a very essential part of making Hand-tufted Rugs, It holds the tufts in place

After Washing, the rugs are put in open area to dry, The Sun light & Wind are the main source of it. This process requires proper care & deep knowledge of it. Silk rugs are very delicate as compared to wool and they require light weather.

It is an essential process to make the sides straight otherwise the carpet has some curved edges.

Binding protects the edge of the carpet from wear and from unravelling, binding can add not only function but style to match your decor.

After rugs are knotted from the loom, they are brought to the cutting & clipping department, where experienced workers clear the pattern & trim the pile with the help of scissors & Machines to get the right color & effect for each design. Trimming requires a meticulous eye for detail, so as to not compromise the design and color scheme.

The final stage involves neatly wrapping the sides of the rug in a yarn that matches the design. Experienced hands know where to cut and where to trim the piles in order to get the right color and effect for each design.

The finished carpet is taken to the washing plot where it is washed manually and mechanically by using filtered water & environment-friendly detergent, This process is required for the shine of the carpets and more importantly brings alive the beauty of the design

Packing is the final step, where the finished carpets are tagged and ready to be shipped to our customers. we make sure to arrive the goods in perfect condition, we take all the necessary steps in packing to avoid strain, scar, tearing the packing, dust, dirt, raindrops, bending, creasing, etc. we professionally clean the rugs prior to packing and spray a fabric-safe moth spray to keep the moth away, we do strong packing by putting 3 different types of fiber, at last, we take pictures of packing so that we can share them with our clients and have a record for future reference.